by The Team

KING NEPTUNE:

As this is being written, much of the Neptune is already at Caloundra

with the remainder expected to arrive in early March. Before we

could contemplate moving the aeroplane, we had to pay for it!

It is most pleasing to report that this was achieved in a remarkably

short time thanks to some excellent trading days over Christmas/New

Year. We thank our front desk slaves for being there to rake it

in! We also thank Peter Graves for a significant donation towards

the cost of the acquisition. (It will be remembered that Peter

also assisted us with the purchase of the Iroquois). The following

report on the Neptune recovery has been compiled from notes supplied

by former Mareeba boy Geoff Webber who participated in the recovery

in several roles, including that of official scribe/photographer.

Geoff also gave distinguished service as Chief Cook although it's

doubtful if he washed any bottles!

NEPTUNE RECOVERY:

A call for volunteers to recover the Neptune resulted in a team

of 14 of which 9 flew to Cairns on Saturday 6th February, 4 drove

and 1 went by train. Although some may have been tempted to think

that the project was overstaffed, as it turned out, all fourteen

were fully occupied (and exhausted!) during the planned one week

recovery. We must make special mention of Bob Meredith who drove

the QAM truck and trailer from Caloundra to Mareeba with tools,

ladders, generator, compressor, marquee, eskies and all necessary

equipment that couldn't go as airline baggage or which might be

frowned upon as cabin baggage. It was Bob's choice to go solo

and despite initial reservations it was realised that this is

what Bob has done for much of his working life so he was cleared

to depart subject to regular sitreps.

The team was based at a motel conveniently located 5km from the

Beck Museum. The work day started at 7am with departure from the

motel via a hired 12 seater bus. The Beck Museum kindly provided

access to toilet facilities and opened and secured the work site

each day.

Weather on most days was fine, hot and sunny. Temperatures soared

above 30C with humidity ranging from 55% to 90% depending on time

of day. Brief showers interrupted preparations on the final day

causing some concern. However, the only heavy rain occurred on

Thursday around 1.30pm halting crane progress for approximately

one hour.

Power on site was provided by the QAM generator and a compressor

for power tools. Ducted fans were set up to provide adequate ventilation

for those working inside the confined fuselage compartments. Bottled

water was provided to all workers on a regular basis to avoid

the risk of dehydration.

Most volunteers provided their own breakfast supplies at the motel.

Lunches were prepared on site each day and paid by volunteer contribution.

The menu consisted of a variety of healthy cold meats, salads,

fruit and vegetables, buttered bread rolls. Tea, coffee, cold

drinks and cold water were served with the buffet style lunch

around noon each day.

Transport of the aircraft components was pre arranged with Russell

Transport (who transported our Fokker Friendship from Tamworth)

and cranes were hired locally from Mareeba Crane Hire. Two 20

tonne Franna cranes and one 30 tonne crane supported and lifted

the various sections. These were loaded and packed onto two low

loaders and two flat top trucks which commenced arriving from

Thursday morning through to final departure on Friday afternoon.

The safety record was excellent, with only a couple of cuts to

fingers and some bruises. All team members were exhausted at the

end but satisfied with a well executed team effort, knowing that

it could not have been accomplished with fewer volunteers or in

less time. All aspects of the operation brought their challenges

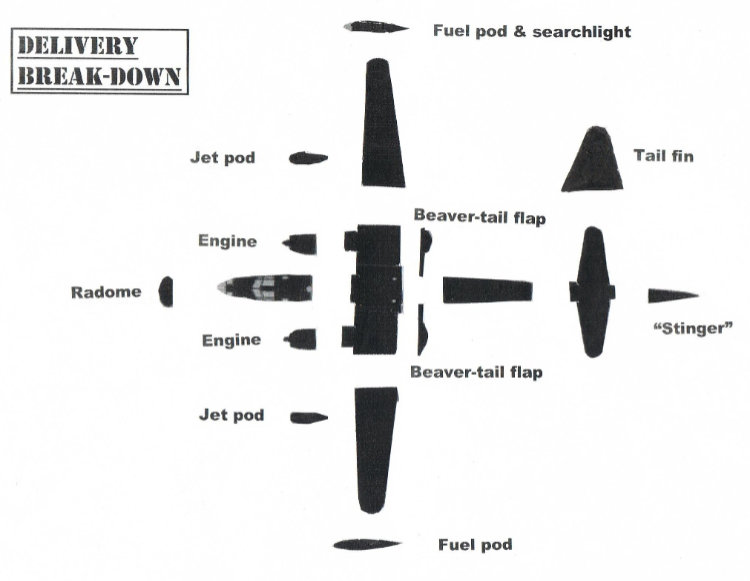

but separation of the fuselage into four sections was particularly

difficult, as we expected it to be. While we are delighted that

A89-277 is virtually complete inside, this complicated access

to the hundreds of bolts that hold the fuselage sections together.

All seven working days commenced at 7am and wound down around

4-5pm. Thursday and Friday turned into 12 hour days on site as

time was running out and the forward fuselage still clung stubbornly

to the centre section. These two sections were eventually separated

at 1.30pm on Saturday, the final day. We had hoped to transport

the centre section at an angle to reduce its width but unfortunately

this proved impossible. In its current state, the width of the

centre section is such that it would require a full Police escort

which would result in a total cost of $29,000. Thankfully there

is another much cheaper option and accordingly several of the

team will be returning to Mareeba in March to remove the two engine

nacelles from the leading edge of the wing. Thankfully Lockheed

anticipated that we would need to do this!

QAM'S NEPTUNE KINGS:

The Neptune team comprised the following members (in alphabetical

order).

Malcolm Bird

Angelo Calleja

Ray Deasy

Cameron Elmes

Bill Furlong

Dave Geck

Peter Harrington

Greg Mackenzie

Bob Meredith

Keith Richardson

George Saliba

Nick Sayer

Geoff Webber

Tony Whitten

Joining the team at Mareeba were local residents Greg Keller and

Bill Parry. Thank you all.

NEPTUNE'S DIARY:

Saturday 6th February: The team assembled on site at approximately

1.30pm to assess the aircraft and unpack the truck and trailer.

The marquee and tables were set up ready for work to commence

in earnest on Sunday. Intermittent showers give cause for concern.

Day 1 - Sunday 7th February:

Norm Beck opened the gates at 7am and the QAM President/Team Leader

briefed the team on priorities and daily procedures. Emphasis

was placed on safety gear, the First Aid kit and the importance

of regular fluid intake and keeping an eye on one another. Initial

tasks were allocated as follows: Engines and props - Peter, George

& Ray. Radome and bomb bay doors - Bill, Keith, Greg, Mal & Angelo.

Open hatches & examine bolts - Tony & Dave. Remove fibreglass

stinger using the truck as a work platform. Locate fans inside

the fuselage. Document and photograph internal equipment - Nick.

Begin removal of fuselage bolts - Tony, Dave & Nick. Construct

timber support cradles - Mal & Bob. Co-ordinate lunches & purchasing

supplies - Greg and Geoff. Keeper of daily diary, photography

and provision of water bottles - Geoff. Time lapse camera - Dave.

By 8.10am the tail stinger was off. The radome was then removed

as were the bomb bay doors which were secured in a safe area.

Local recruits Bill and Greg continued with removing antennae

and the toilet which obstructed the fuselage bolts. Work paused

at 11am for a group photo for the local Mareeba Express reporter.

Progress is slow with removing the many engine firewall connectors

but 95% is done and the engines should be ready for removal on

Monday. Keith disconnects hydraulic connectors in the cockpit

and bomb bay. Mal and Bob make good progress manufacturing timber

support cradles and carpet padding. Tony and Dave have removed

most of the bolts in the rear fuselage join. Works concludes at

4pm with progress exceeding expectations.

Day 2 - Monday 8th February:

At 8am a 20 tonne Franna crane and a 30 tonne crane from Mareeba

Crane Hire arrive on site. Norm Beck co-ordinates the use of one

crane to retrieve the wings, fin, rudder and jet pods which were

never fitted at Mareeba. These items plus a spare R3350 engine

on stand were located in a nearby shed. A storm passes through

at 1.30pm which renders the ground too wet to attempt to lift

the engines so this is postponed until Tuesday. Work continues

on removing bolts and disconnecting hydraulic lines. Bolt removal

from the rear fuselage by Tony and Dave is almost complete. The

day finishes at 4.00pm.

Day 3 - Tuesday 9th February:

At 9.00am the port engine is off, closely followed by the starboard

engine at 9.45am. The timber support cradle is fitted to the still

attached rear fuselage and held in place with straps. The cowls

were reattached to the engines and wrapped in plastic. Work concluded

at 4pm. A heavy rain storm passed over at 7pm.

Day 4 - Wednesday 10th February:

The day dawned fine and sunny albeit hot and humid. The locals

claim it is the hottest day for many years. Removal of the fuselage

bolts is slow frustrating work in the stifling heat inside the

aircraft. Locally sourced ducted fans help to keep the internal

temperature down while Bill, Keith, Tony and Dave struggle to

maintain their fluid levels inside the fuselage. At 12.15pm two

Franna 20 tonne cranes arrive late and one has to return to be

replaced by a 30 tonne crane. With cranes and harnesses in place,

the aircraft is lowered to the ground as the undercarriage retracts.

The generator and compressor are working hard in the heat so a

second compressor is hired locally. To comply with width restrictions,

the flaps have to be removed and Bill, Greg and Tony tackle this

difficult job. Work concluded at 4pm.

Day 5 - Thursday 11th February:

While the team struggles to meet schedule, it doesn't help when

a truck booked for 1.30pm turns up at 7.30am. That's only six

hours early and the driver expects us to pay for his waiting time!

Cameron makes several calls to Russell Transport management and

things are soon sorted. A second truck and a Franna crane turn

up at 9am while fuselage bolts continue to present their challenges.

After discussions with the truck drivers it is necessary to realign

the props and cover the blade tips with coloured markers. To provide

a lower working height for removal of the rear fuselage the crane

is used to lift the nose. With several bolts refusing to yield

it is decided to allow a heavy dose of magic fluid to do its work

while the exhausted workers have lunch. Work resumes after lunch

but heavy rain at 1.30pm causes further delays and it is not until

4pm that the rear fuselage with tailplane attached finally separates.

The trucks are loaded for departure early on Friday. The work

day concludes at 7pm as the sun sets and light fades.

Day 6 - Friday 12th February:

The day started early at 6.30am to make final checks of the two

loaded trucks which departed in convoy at 9.30am heading down

the Palmerston Highway for Townsville, 277's former home. A third

truck departs at 11.30am with the two wings. Mal and Bob continue

work on the cradle to support the centre section. A crew from

WIN-TV arrived at 11am to conduct interviews. A Franna crane arrived

at 2.30pm to lift the rear fuselage but again there are hidden

bolts to frustrate the operation. It is not until 5pm that the

rear fuselage is free and loaded on to a waiting truck along with

the stinger, tip tanks and J34 jet engine. Work concluded at 6.30pm.

Day 7 - Saturday 13th February:

The fourth truck departed at 8am. This leaves only the forward

fuselage and the centre section to be separated. The support cradle

is fitted to the forward fuselage and the crane takes up the weight

as Dave and Tony are incarcerated inside to remove the final bolts.

At 1.30pm the forward fuselage is free. Due to transport complications,

the two remaining sections are left on site for later collection.

All that remains to be done is clean up the site and pack the

QAM truck. After farewelling the Becks, the weary team retires

to prepare to fly back to Brisbane on Sunday morning.

Thank you to all who participated in this recovery project. Thanks

also to Bob De La Hunty of HARS for manning a telephone help desk

during the operation.

|